thyssenkrupp Automation Engineering GmbH

Booth number: 3927

www.thyssenkrupp-automation-engineering.com/en

About us

thyssenkrupp Automation Engineering is an internationally operating business unit of the Automotive Technology segment of thyssenkrupp AG. The company combines all activities in the field of powertrain and battery assembly with a major focus on the transformation towards electro-mobility. For its customers, the company is a strong and reliable partner that optimizes their value chain and strengthens performance.

Address

Zeißigstraße 12

09337 Hohenstein-Ernstthal

Germany

E-mail: automation.engineering@thyssenkrupp-automotive.com

Phone: +49 3723 62 0

Internet: www.thyssenkrupp-automation-engineering.com/en

901 Doris Road

48326 Auburn Hills

United States

E-mail: systemengineering.US@thyssenkrupp-automotive.com

Phone: +1 248 3408000

Internet: www.thyssenkrupp-automation-engineering.com/en

Av. Del Marqués 36A Parque Industrial Bernado

76246 Quintana El Marqués, Querétaro C.P.

Mexico

E-mail: systemengineering.mx@thyssenkrupp.com

Phone: +52 442 192 4000

Internet: www.thyssenkrupp-automation-engineering.com/en

Contact person:

Kristin Lüdemann

Business Development

E-mail: kristin.luedemann@thyssenkrupp-automotive.com

Phone: +4915234634941

Products & Services

We are the first choice for challenging automation projects!

Product and Competence Overview:

Handling & Transport

Enabling Processes

Inspection

MAU

Services

Formation

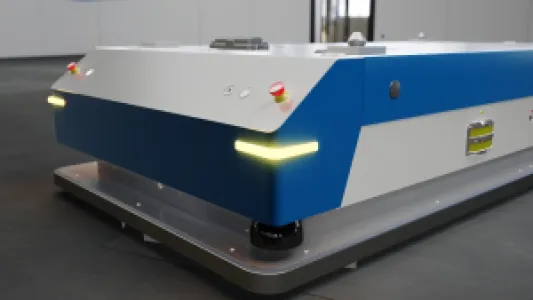

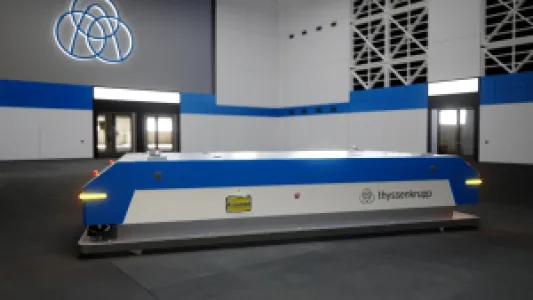

Automatic Guided Vehicle (AGV)

The innovative automated guided vehicle (AGV) from thyssenkrupp Automation Engineering is the optimal solution for your requirements.

We offer customized interfaces, including mounts for rotary housings, roller conveyors, and workpiece carriers – all from a single source:

agv4production2800

agv4production2000

Thanks to the latest charging technology, the AGV is ready for use in no time and ensures maximum availability.

Pulse Phase Thermography

Pulse Phase Thermography not only sees the surface of laser weld seams, but can also look inside - similar to X-ray methods - and thus determine the weld cross-section.

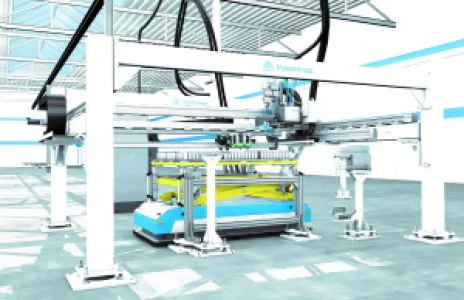

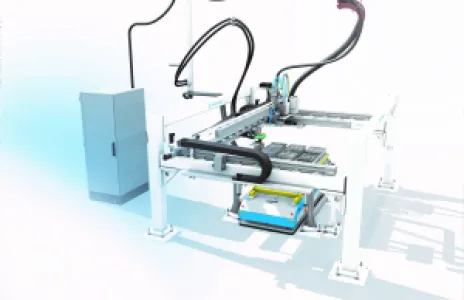

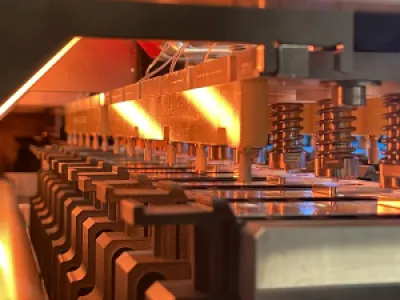

High Speed Laser

With our innovative HSL system, we offer an innovative on-the-fly laser welding system for different battery sizes.

Laser welding of battery modules and packs with high accuracy and high throughput, regardless of cell format. The exclusive laser equipment offers efficient utilization of up to 98%:

HSL with 2 hold-down devices

HSL with 4 hold-down devices

Our systems can be flexibly integrated into transport technology such as roller conveyors or AGVs. All process parameters are seamlessly logged in the measuring computer or directly in your MES system – optionally also in combination with our MES solutions ADM and QDM.

Formation

Technological leadership through Fast Formation & Fast Aging

Fast Formation

Our innovative Fast Formation processes enable a reduction in cell formation time of up to 45% – while maintaining consistent quality, safety, and cycle stability.

Fast Aging

Through data-based process optimization and intelligent models, we reduce the conventional aging time from 10 days to less than an hour – together with our technology partner Limatica.

AI-supported processes

With AI-based smart processing – including EOL cell evaluation, system training, and automated process control – we achieve adaptive, scalable, and efficient cell production.

Battery Systems

Module Assembly / Pack Assembly

cell-to-pack / cell-to-car

Begin-of-Line Test

End-of-Line Test

Service

Virtuell Commissioning

Laser Competence Center