Weil Technology

Booth number: 4326

weil-technology.com/en

About us

We empower our customers to fully leverage their potential in the production of sheet metal and metal assemblies in order to achieve economic goals and sustainable success. Our manufacturing solutions are deployed wherever change takes place and tomorrow’s products are created.

We have been developing machines and modular systems for more than 35 years, which are characterized by the combination of innovative laser, clamping and automation technologies and enable versatile production steps in the processes forming, cutting and joining.

Our solutions and services are characterized by expertise, flexibility and commitment. Our central goal is to provide added value for our customers and to satisfy their needs, as has been demonstrated by thousands of installations worldwide and our many long-term partnerships.

Address

25921 Meadowbrook Road

Novi, MI 48375

United States

E-mail: Information@weil-technology.com

Phone: +1 248 344 2211

Internet: weil-technology.com/en

Neuenburger Straße 23

79379 Müllheim

Germany

E-mail: info@weil-technology.com

Phone: +49 7631 1809-0

Internet: weil-technology.com/en

Contact person:

Regional Sales Manager | Northeast US + Canada John Sullivan

E-mail: jsullivan@weilengineering.com

Regional Sales Manager - Southeast Kelly Bigham

E-mail: kbigham@weilengineering.com

Regional Sales Manager - Midwest Peter Eigenmann

E-mail: peigenmann@weilengineering.com

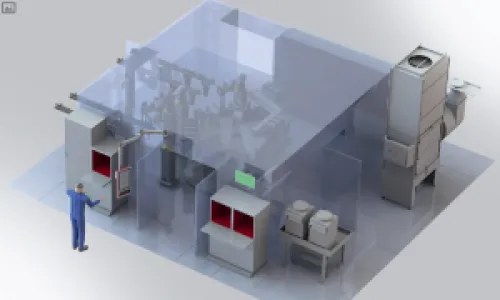

Prismatic Cell Housing Manufacturing Cell

Longer prismatic cell housings are usually produced either with continuous roll-forming or cycled pressforming processes. Weil Technology now offers a new alternative and fast process with a compact system allowing for stainless steel housings with wall thickness of as low as 0.15 mm.

The innovative system can produce a cell housing made of stainless steel directly from a coil or blank. We draw on our decades of expertise in short tube production. After the optional blank trimming, a tube is rounded in the first part of the system and reliably laser-welded. In the next step, the tube is expanded into its final shape and calibrated. This allows stainless steel cell housings with material thicknesses as low as 0.15 mm to be produced economically and at high outputs in a compact space.