senswork GmbH

Booth number: 4028

senswork.com

About us

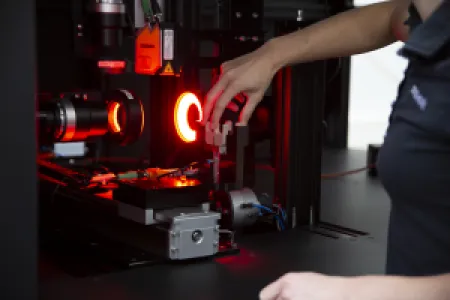

senswork is a leading provider of end-to-end solutions for machine vision, automated inspection and Vision AI. Our automation and quality assurance solutions are used daily in numerous industries, ranging from automotive and mechanical engineering to medical technology. From our locations all over the world, we serve renowned customers from industry and research. We offer everything from a “one stop shop”, from the initial concept to the integration of the finished solution. We analyze your tasks in detail and address your specific requirements to develop a precisely fitting camera system, the perfect test station or the ideal test device.

Address

Gewerbepark Lindach D 3

84489 Burghausen

Germany

E-mail: info@senswork.com

Phone: +49 86774099580

Internet: senswork.com

2109 West Market Street Suite 141

37604 Johnson City

United States

E-mail: info@senswork.us

Phone: +1 423.283.8550

Internet: senswork.com/en-us/

1 Scotts Road #21-10, Shaw Centre

228208 Singapore

Singapore

E-mail: info@senswork.sg

Phone: +65 31635264

Internet: senswork.com/

Contact person:

Products & Services

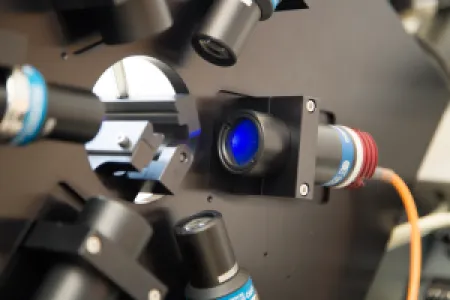

Inspection Technologies

2D and 3D inspections

3D metrology

Label inspection

Position recognition

Surface inspection

Completeness check

Deep Learning (AI)

Robotic Vision

Offer

Optical measuring and inspection equipment from a single source

Inline inspection systems

Feasibility studies, consulting

Concept development, contract development

Complete systems & special solutions

System engineering, prototyping

Integration and commissioning of systems

Components: Cameras, optics, lighting

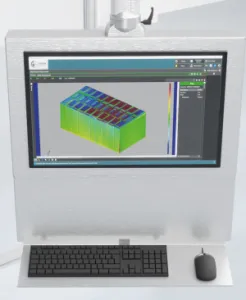

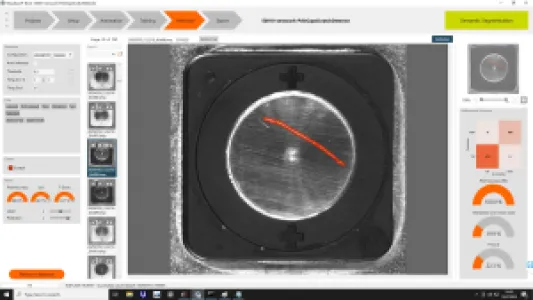

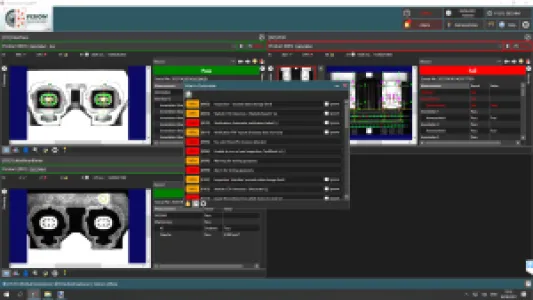

VisionCommander

Customized machine vision systems require the appropriate software. Especially when it comes to performance, data tracking or flexibility in inspection, standard software products are no longer sufficient. With VisionCommander® you get powerful machine vision software for all industrial use cases such as 2D, 3D, 360° inspection and Deep Learning (AI) for automated measurement and inspection. The integrated manufacturer-independent hardware interface allows you to always use the most suitable camera technology without compromise.

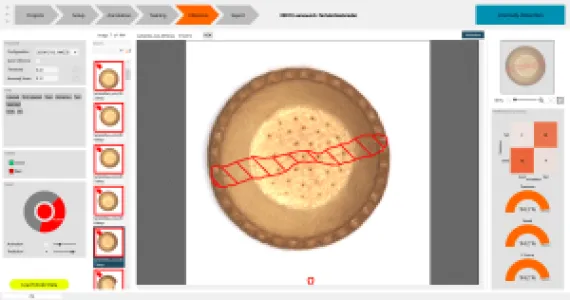

Neuralyze

Tasks in optical quality assurance that were previously considered difficult or unsolvable can often be effectively solved with the help of AI. As an expert in Vision AI, senswork is developing the Neuralyze® software toolkit, which analyzes image data using neural networks. Difficult-to-detect properties such as reflection or transparency of component surfaces, or even complex features such as those found in foodstuffs, can thus be reliably checked. Neuralyze® expands the range of tasks that can be solved with industrial image processing: The decisive step in implementing your vision of 100 % quality.

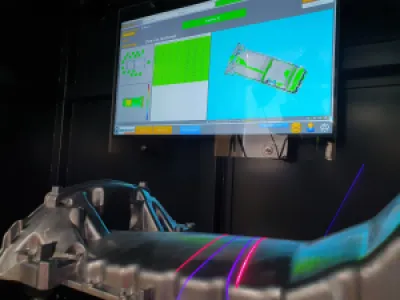

ZScan

Optically measuring large and complex parts equivalent to a coordinate measuring machine (CMM) and automatically aligning them with the CAD model - this can be done in just a few seconds with ZScan® - especially for very large parts with demanding surfaces.