Laserline GmbH

Booth number: 4528

www.laserline.com/en-int/

About us

Laserline GmbH, based in Mülheim-Kärlich near Koblenz, was founded in 1997 and is a world leader in the development and manufacture of efficient, modular diode laser systems at blue and infrared wavelengths. Laserline high-power diode lasers achieve output powers of up to 60 kW and a wall-plug efficiency (WPE) of over 56%. Based on decades of experience, Laserline develops customized laser solutions for industrial applications – including high-quality beam-shaping optics for the realization of variable spot geometries – and has established itself internationally as a reliable partner. More than 8,000 high-power diode lasers from Laserline are currently in use around the world, demonstrating their performance in a wide variety of processes and applications. The laser technology specialist currently employs around 400 people and has international subsidiaries in the USA, Mexico, Brazil, Japan, China, South Korea and India as well as representatives in Europe (France, Great Britain, Italy) and in the Asia-Pacific region (Australia, Taiwan, Singapore).

Address

Fraunhofer Str. 5

56218 Mülheim-Kärlich

Germany

E-mail: info@laserline.com

Phone: +49 2630 964 0

Internet: www.laserline.com/en-int/

1800 Wyatt Drive, #9

95054 Santa Clara, CA

United States

E-mail: info-usa@laserline.com

Phone: +1 408 834 4660

Internet: www.laserline.com/en-int/

37659 Schoolcraft Road

48150 Livonia, MI

United States

E-mail: info-usa@laserline.com

Phone: +1 248 826 5041

Internet: www.laserline.com/en-int/

Avenida Eugenio Garza Sada 155 Oficina 2A

Colonia Lomas del Tecnológico

C.P. 72810 San Luis Potosí, SLP

Mexico

E-mail: info-mexico@laserline.com

Phone: +1 408 834 4660

Internet: www.laserline.com/en-int/

Contact person:

Dan Robinson

General Manager, US Operations

E-mail: daniel.robinson@laserline.com

Wolfgang Todt

Vice President Sales

E-mail: wolfgang.todt@laserline.com

Joseph Krause

Applications Engineer

E-mail: joseph.krause@laserline.com

Products & Services

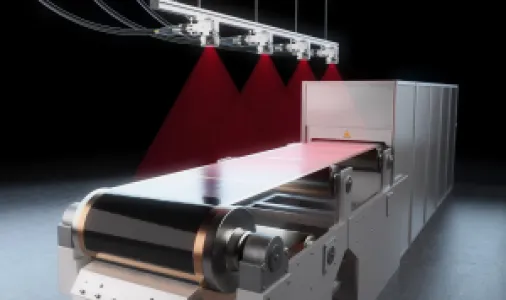

Laserline presents energy-efficient laser applications for industrial material processing in the field of electromobility and battery production. Product highlights include the LDF 30,000 DR and LDF 15,000 DR diode lasers – two high-efficiency laser systems that support a diode laser-based drying process for the efficient, economical and environmentally friendly production of lithium-ion batteries. Recently added to our portfolio is the LDL Direct Diode Laser, which impresses with a wall-plug efficiency of over 56% and a compact design, making it ideal for thermal processing applications. For the first time, our diode lasers enable the production of anodes and cathodes in a roll-to-roll process, offering an alternative to the market-dominating convection drying in electric or natural gas convection ovens. Compared to a conventional GigaFab drying line, this technology delivers operating cost savings of 20 to 30 percent and reduces the required production area by half. Moreover, drying times can be significantly shortened – by up to 60 percent – without compromising quality, marking an important milestone on the path toward CO₂-neutral and competitive battery cell production.

Blue Diode Lasers LDFblue and LDMblue

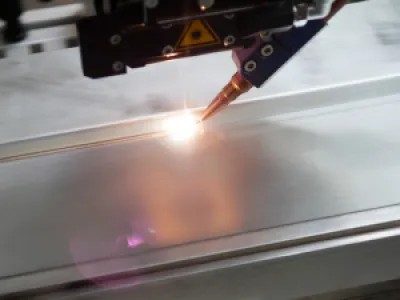

6 kW Blue Diode Laser - The blue diode laser revolutionizes the processing of copper, gold and its alloys in various ways. The generation of up to 6 kW (cw) laser power in the 445 nm wavelength range is unique for industrial lasers. This wavelength is ideal for the processing of highly reflective materials since its higher absorption allows significantly lower intensities and larger laser spots.

Blue High Brightness Laser – The new LDFblue wbc lasers feature high beam qualities of 4mm.mrad and better. This laser with high focusability is ideally suited for precision applications, including Laser Powder Bed Fusion and copper welding. The system provides an industry-proven design with a familiar Laserline interface.

Tailored Diode Laser Solutions – From Compact to High-Power Systems

Laserline is the international leading manufacturer of diode lasers for industrial materials processing and sets a new benchmark for high power diode lasers. The modular LDF VG6 series is versatile in use, offers 45 kW laser power in less than one square meter footprint, and an electrical efficiency of over 50 percent – even at high beam qualities. With a range of different power levels, cooling systems and control interfaces, the LDF series can be individually configured to changing requirements.

The Laserline LDM series includes highly compact beam sources as 19" rack mount modules. This technology offers simplified laser integration in machines or systems. It combines the diode stacks, a fiber-coupling unit, the power supply and integrated cooling as well as control electronics to monitor and control the laser.

With increased beam quality and laser power up to 10kW now available in the newer VG7 version LDM, Laserline again sets the standard for compact high power diode lasers.

Together, the LDF and LDM series offer a comprehensive portfolio of diode laser solutions – scalable, efficient, and precisely tailored to your industrial requirements.

Direct Diode Laser – The Efficiency Champion in Heat Treatment

The new LDL Direct Diode Lasers offer a compact and efficient solution for modern heat treatment. Thanks to their direct photon emission, they achieve a wall-plug efficiency of over 56%, setting new standards in heat treating applications. The compact laser systems are currently available with output powers of over 30 kW. Due to their simple system architecture, they are not only cost-effective but also easy to implement. The modular system design allows for customer-specific and tailor-made solutions. The segmented power submodules can be precisely controlled, which opens up a wide range of beam shaping options such as spot trimming. The ability to work with minimal or remote working distances provides maximum flexibility.

High-Efficiency Heat Treatment and Drying with LDF DR and OTX Optics

Laserline’s LDF DR high-efficiency diode laser system is a powerful and flexible solution for a wide range of industrial heat treating and drying applications. With its compact footprint, instant heating capability, and precise temperature control, it is particularly well-suited for use in battery production and surface processing. Based on the proven LDF platform, which has proven itself for over 25 years, the LDF DR features a modular design with scalable laser power between 15 and 30 kW. Processing optics such as the OTX Optics can be easily exchanged, allowing for straightforward maintenance and adaptation to specific application requirements.

The OTX Optics are specially developed for use with Laserline diode lasers. They deliver highly efficient, homogenized beam profiles with widths up to 1.5 meters. The ultra-wide beam technology is successfully used in the production of lithium-ion batteries in a roll-to-roll process, for example.

Processing Optics OTS-5 with Multi-Spot Module

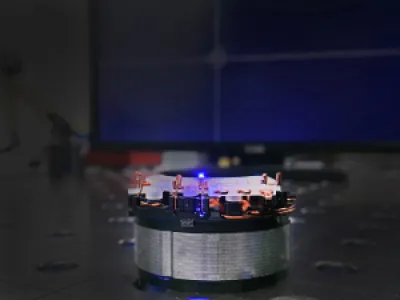

The Laserline OTS optics are designed for industrial material processing and optimized for use with Laserline's diode lasers. The innovative Multi-Spot module enables the realization of almost any desired spot geometry and intensity distribution, achieving high speeds and attractive weld or braze seams.

Its Spot-in-Spot design ensures efficient welding of both asymmetrical and symmetrical seams with minimal spatter and adaptable penetration, making it ideal for the production of battery boxes. Additionally, the diode laser-based process supports numerous beam shaping options, allowing precise adaptation of power input to each specific component. This significantly reduces hot cracking.